Unique and Handcrafted

We specialize in creating particularly strong sheets of decorated paper, preferred by bookbinders and artists for over twenty-five years.

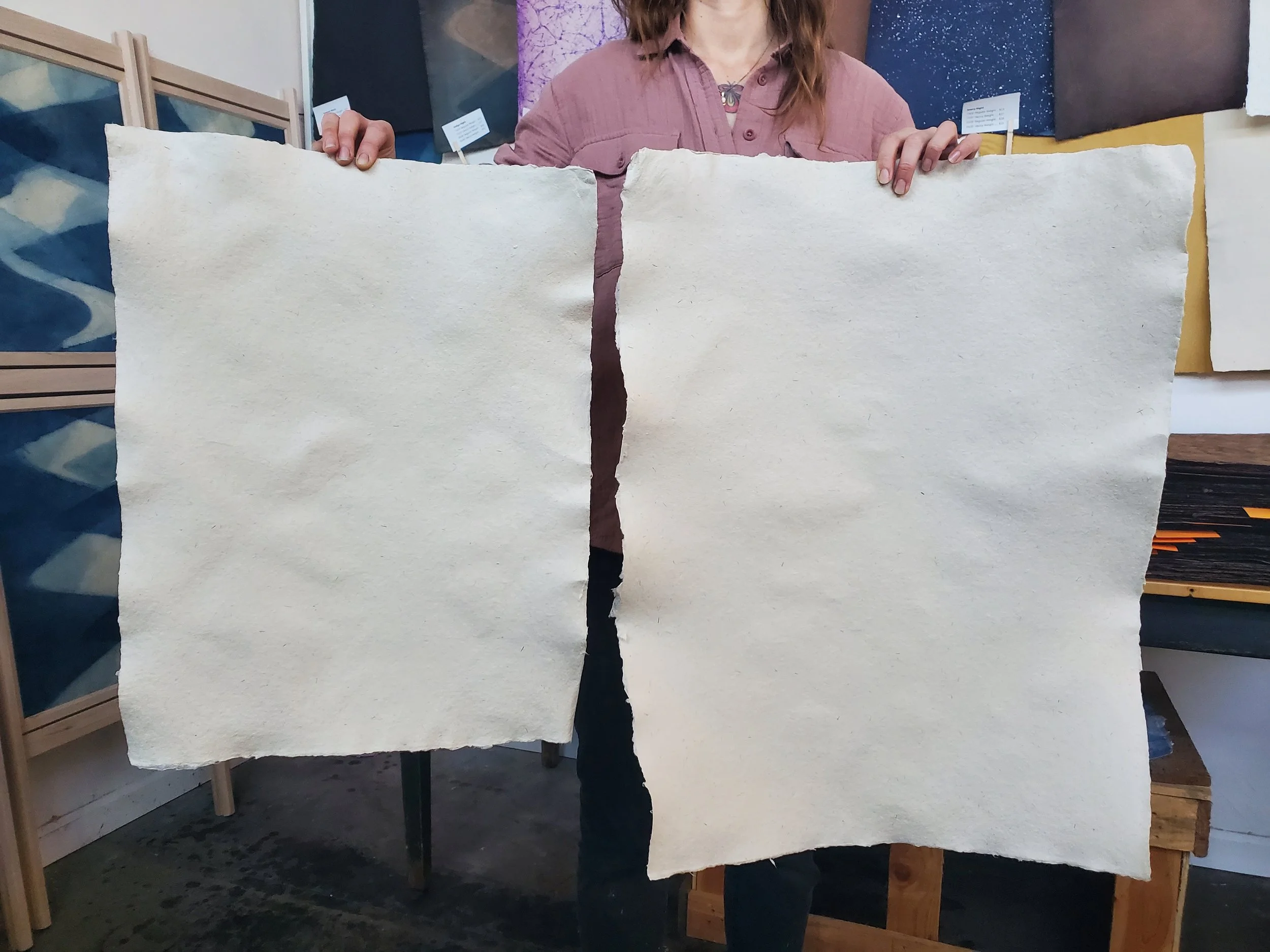

Each sheet of paper is formed and colored by hand. We use 100% Belgian Flax in the majority of our papers, with a smaller selection of Cotton Rag sheets. Natural dyes such as Black Walnut, Indigo, Persimmon, and Pomegranate Rind are applied individually and in combination to the surface of the sheet in multiple layers. Our catalog also features papers made with pigmented pulp, inclusions, and other surface treatments. The process from fiber to finished sheet can take as many as twenty days to complete.

No two sheets of Cave Paper will ever look exactly alike. We balance an exceptional standard of quality with an appreciation for the organic nature of our craft. It is part of the joy of our paper and process!

A Guide to Paper Weights and Dimensions

We measure weight by thickness of the sheet. Thickness is consistent within each sheet, and there is a small range for each category of weight.

Regular Weight sheets range from 0.012” - 0.015” in thickness.

Heavy Weight sheets range from 0.020” - 0.024” in thickness.

In general, Regular Weight is recommended for projects where you may be wrapping book board or similar.

All papers are available in two dimensions. We sheetform using moulds sized 18x24” and 24x30”. Because we air-dry our papers, the fiber is allowed to shrink, and the finished sheets are smaller than the moulds they are formed on. There is some variation in finished dimensions as well. For this reason, we list our dimensions as:

17x21” and 21x27”.

For 30x40” sheets, please inquire for availability.

FAQs

-

In addition to our online shop, Cave Paper can be found at:

Hiromi Paper, Culver City CA — www.hiromipaper.com

Talas, Brooklyn NY — www.talasonline.com

If you're in Tucson, contact us to set up a visit to shop in-person!

-

Handmade paper does not have a grain in the same way that machine-made paper does. This is because of the way the fibers interlock when each sheet is formed individually in a mould. Machine made paper is formed by depositing pulp onto a conveyor, resulting in a strong directional grain.

Our paper has a slight short grain because of the orientation of the mould as it is dipped into the vat. However, it will not be as pronounced as what you will find in machine-made papers.

We recommend scoring your paper with a bone folder before folding or tearing the sheet in any direction.

-

Sizing is any substance incorporated into the paper pulp, or applied to the surface of the sheet, to act as a protective filler or glaze.

Internal sizing is integrated into the paper pulp for the retention of pigments, dyes, and other fillers. It may also effect how much the fiber shrinks as it dries.

External sizing is applied to the sheet after it has been dyed to prevent any coloring from transferring from the sheet. It also creates a more abrasion-resistant surface.

In our Shop, you can find details about how each sheet is sized and what options are available.

-

We are happy to work with you to create unique papers for your project!

Information about our custom order process and examples of our previous projects can be found here.

-

Current job openings and internship opportunities may be found here.

We look forward to hearing from you!

-

We offer studio tours about once a month. If there are no upcoming tours listed, stay tuned for updates by joining our email list and following us @cavepaper. If you’re interested in organizing a tour for a group, contact us to discuss the options!

-

Yes! Check out the LEARN page for all upcoming workshops and events.

All workshops and events take place at our studio, 846 N. Stone Avenue Tucson AZ, unless otherwise noted.

Sustainable Practices at Cave Paper:

Alternative Water Systems

-

Grey Water Collection

Water is integral to papermaking! And on a production scale, we use quite a bit of it.

When Cave Paper relocated to Tucson, AZ in July 2020, we knew that we would need to prioritize designing new systems around water use.

Currently, we collect 200-500 gallons of grey water from every batch of fiber we process and use it to water garden basins. Our goal is to collect 100% of grey water generated by our papermaking processes by 2024.

-

Rainwater Harvesting

We aim to install infrastructure to harvest rainwater by the end of 2024. This collected water will be filtered before use in fiber processing and sheet formation.

Along with the financial benefit of using less city water and creating a system in which our business will become more resilient, initiating these steps will greatly reduce the impact of our water use at Cave Paper. As the environmental crisis of water scarcity in the Southwest continues to grow, we are dedicated to creating a sustainable model for responsible water systems.

-

2022 Sustainable Earth Small Business Awards Recipient

See the presentation submitted to Sustainable Earth that won us a Small Business Award in 2022! A lot has changed at Cave Paper since then, but our focus on water conservation has only grown.

Based in Tucson since July 2020, Cave Paper is owned and operated by Zoë Goehring.

Cave Paper was founded in Minneapolis in 1994 by Amanda Degener and Bridget O’Malley. They began production in a historic warehouse basement, appropriately nicknamed “The Cave” due to its rough-hewn stone walls, lack of windows, and chilly temperatures.

Thanks to all who have helped carry Cave Paper forward through thirty years of hand papermaking.